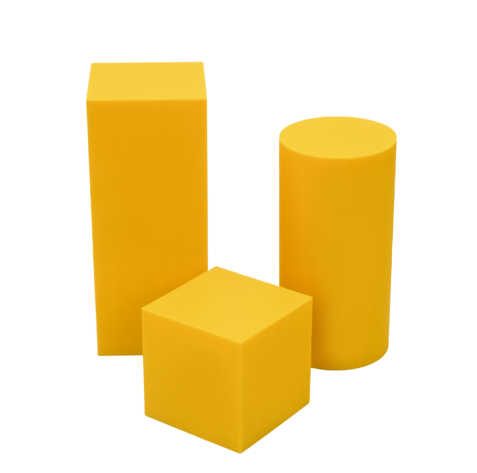

We offer a variety of color options that are ideal for the printing needs of artworks. In addition, we also support color customization services to meet your unique color requirements.

Technical Introduction

3D printing is a technique that takes a digital model and creates a three-dimensional object by adding material layer by layer. It is widely used in prototyping, manufacturing and other fields, greatly shortening the time from concept to finished product. We mainly provide PLA FDM (Fused Deposition Modeling) printing services, which is suitable for a variety of complex and customized projects with high precision and high reliability.

We offer a variety of color options that are ideal for the printing needs of artworks. In addition, we also support color customization services to meet your unique color requirements.

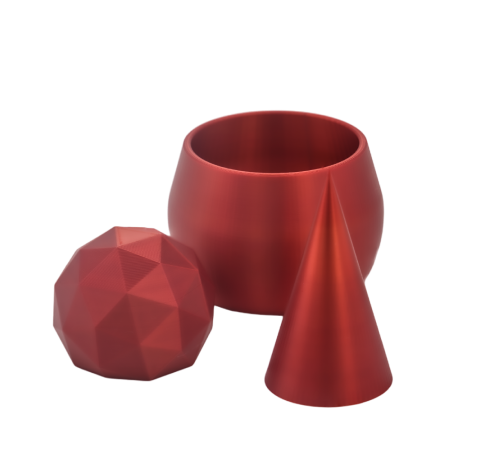

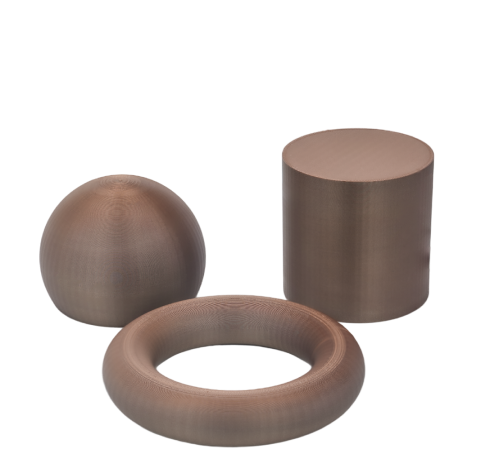

We offer a variety of textures of materials, including metal texture, silk texture, etc., to meet your needs for different projects.

Our PLA FDM printing technology offers high precision and reliability, ensuring that every print meets the best quality standards.

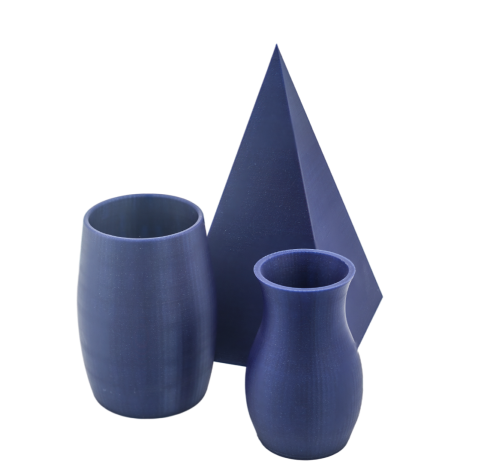

Our multi-color integrated printing technology supports up to four colors at the same time, without the need to separate and combine different colors, increasing your design freedom and printing results.

One click upload file, online quick quote. Support a variety of material selection, support part of the processing process, affordable, cost-effective, fast delivery.

Efficient 24 hours intelligent production line, strong production capacity. Visual tracking of order progress, strict quality control, to ensure punctual and accurate delivery.

Provide fast delivery services, support multiple logistics options, fast and safe delivery. Quality assurance, professional after-sales team 24 hours for you to solve the problem.

We mainly provide PLA printing, because PLA is a biodegradable plastic is more environmentally friendly, but also one of the safest printing materials, color plasticity is very strong. We use PLA+, which is more robust and durable than the conventional PLA, and improves the problem of PLA folding.

| Material | Conventional PLA+ |

| Density | 1.20~1.30(g/cm³) |

| Heat distortion temperature | 55~65(°C) |

| Melting temperature | 150~160(°C) |

| Elongation at break | ≥10% |

| Tensile Strength | ≥50MPa |

| Flexural modulus | ≥2500MPa |

| Bending strength | ≥85MPa |

| Material | Silk PLA+ |

| Density | 1.10~1.30(g/cm³) |

| Heat distortion temperature | 55~65(°C) |

| Melting temperature | 150~160(°C) |

| Elongation at break | 10~15% |

| Tensile Strength | 45~65MPa |

| Flexural modulus | 1600~1800MPa |

| Bending strength | 70~90MPa |

| Material | Metallic PLA+ |

| Density | 1.10~1.30(g/cm³) |

| Heat distortion temperature | 55~65(°C) |

| Melting temperature | 150~170(°C) |

| Elongation at break | 10~15% |

| Tensile Strength | 45~65MPa |

| Flexural modulus | 1600~1800MPa |

| Bending strength | 70~90MPa |

| Material | Model after the ancients PLA+ |

| Density | 1.25±0.1(g/cm³) |

| Heat distortion temperature | 55~65(°C) |

| Melting temperature | 150~170(°C) |

| Elongation at break | 7~12% |

| Tensile Strength | 75~90MPa |

| Flexural modulus | 3000~3400MPa |

| Bending strength | 90~110MPa |

QC sample testing is carried out before each sample is delivered. The inspection includes the overall appearance, size, color contrast and so on.

Effectively ensure data security and eliminate confidentiality risks. Self-operated services are never outsourced, and confidentiality agreements can be signed.

3D Design

We help our clients turn their ideas or floor plans into real products.

Rapid prototyping is a product development method that uses turnkey manufacturing techniques to quickly produce multiple different versions of components for testing and evaluation. 3D printing is often the preferred process for rapid prototyping because it offers an affordable price and the ability to deliver quickly in a short period of time.